FIBREPLATE HYBRID MBR

A Paradigm Shift in MBR Technology

the challenge for aD operators in the uK

The operators of AD facilities face universal issues relating to input feedstocks on the one hand and disposal of digestate produced.

Operator of PAS110 anaerobic digestors face a number of challenges, not limited to the ones listed below!

The alternative to land dispersal is the treatment of the digestate so that it is fit for discharge to sewer. The FIBREPlate Hybrid MBR achieves this through the combination of the strengths of hollow-fibre & Flat-sheet membrane technologies while eliminating the weaknesses of both.

FIBREPlate :

Process integration

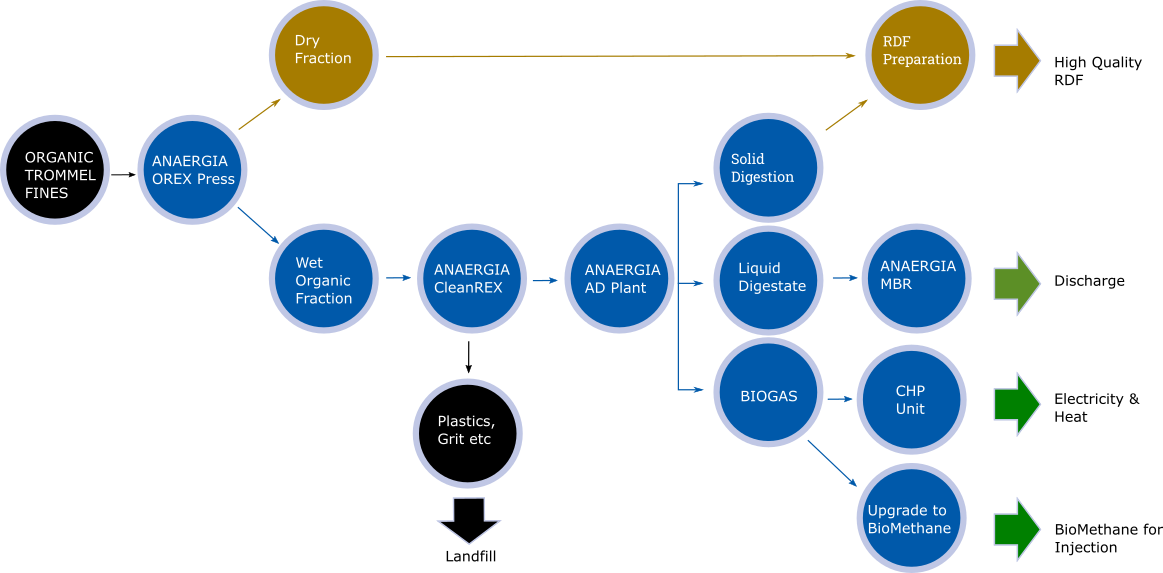

A FIBREPlate MBR Integrated Into A Typical Organic Trommel Fines Processing Facility

Key Anaergia Technologies deployed – OREX Extrusion Press, CleanREX Dynamic Cyclone and FIBREPlate Hybrid Hollow Fibre/Flat Membrane MBR.

The AD digestate produced Is not PAS110 compliant, but can be prepared for discharge to sewer using the FIBREPlate Hybrid MBR.

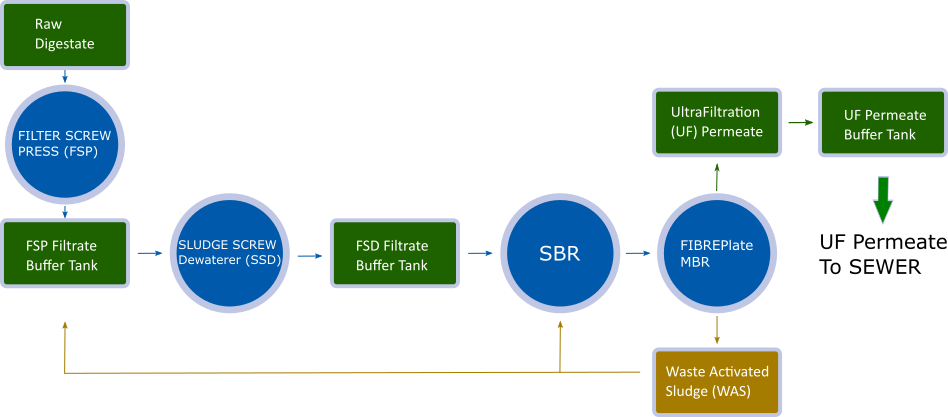

The unique Hybrid Hollow Fibre / Flat Membrane MBR Ultra-Filters the digestate, which has had its nitrogen content removed by Nitrification-Denitrification as shown below.

Non-PAS110 Certified AD Digestate