ORGANIC TROMMEL FINES

A Strategy For The Removal Of Biowaste From Trommel Fines

the challenge for MRF operators

An estimated 5 million tonnes of organic waste are sent to landfill each year in the form of Trommel Fines.

This represent more than 70% of the total biowaste disposed of to landfill and until now there hasn’t been a technology capable of separating out the organics from the inert material.

The OREX is a proven, robust and cost effective technology which will extract more than 90% of this organic material

how the orex PRESS SOLVES THE TROMMEL FINES PROBLEM

The OREX Press extracts the organics in Trommel using high pressure (280 bar). The organic component is liquefied, separating it from the non-organic material.

7 million tonnes per year of Biowaste is sent to landfill, with about 5mty in Organic Trommel Fines.

Trommel Fines contain up to 40% grit/glass/stone etc. which makes them unsuitable for direct anaerobic digestion. OREX offers >90% Separation of the organics in Trommel fines.

anergia’s OREX Press extracts 90% of the organics in MSW using a high pressure ram.

A single OREX processes up to 70,000 TPY of Organic Trommel Fines, with less than 1% of inert material such as grit, stones etc.

The OREX Press is a Unique & Innovative Technological Solution for Organic Trommel Fines

process integration

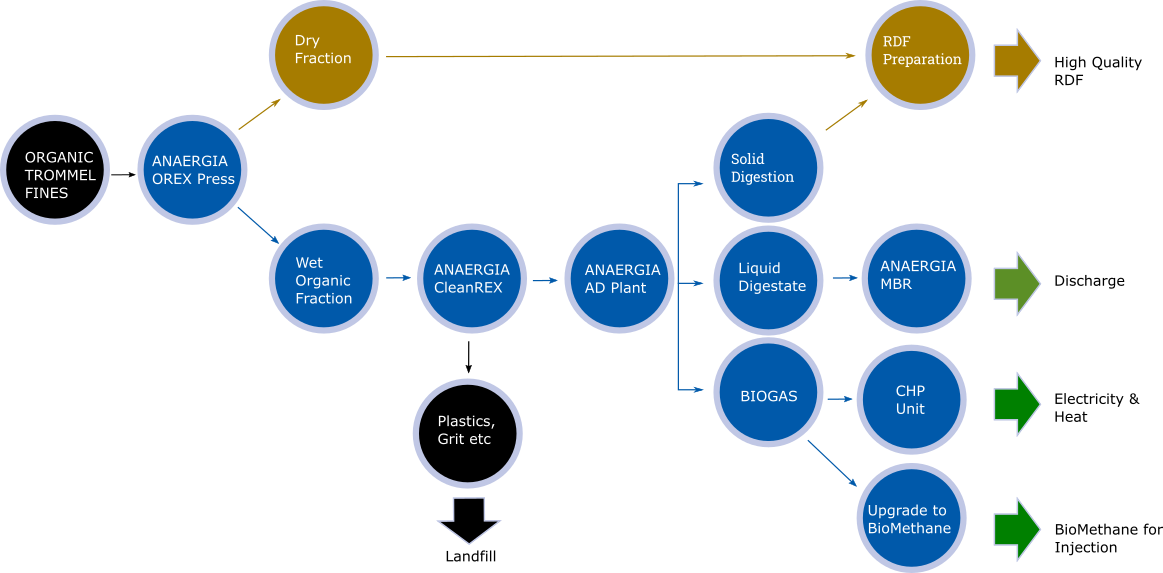

How the OREX Press Processes Trommel Fines from an MRF

Key Anaergia Technologies deployed – OREX Extrusion Press, CleanREX Dynamic Cyclone and FIBREPlate Hybrid Hollow Fibre/Flat Membrane MBR.

The AD digestate produced Is not PAS110 certified, but can be prepared for discharge to sewer using the FIBREPlate Hybrid MBR.

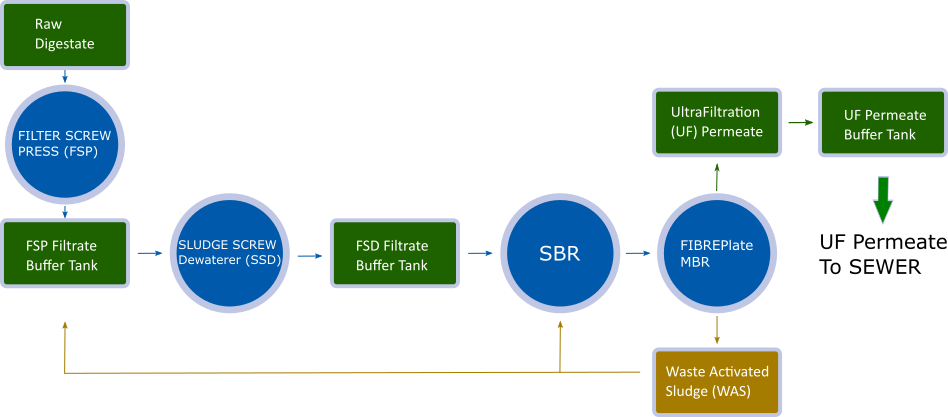

The unique Hybrid Hollow Fibre / Flat Membrane MBR Ultra-Filters the digestate, which has had its nitrogen content removed by Nitrification-Denitrification as shown below.

Non-PAS110 Certified AD Digestate

Nitrification-Denitrification