THE OREX EXTRUSION PRESS

What Is It and How Does it works?

the orex high pressure press

The OREX Press separates more than 90% of all the organic material in challenging waste streams, such as Trommel Fines from MSW and Food & Green Waste.

The Press can be integrated onsite to treat existing waste or allow new waste streams to be processed.

Key benefits include:

alsdkjflkjd

applications

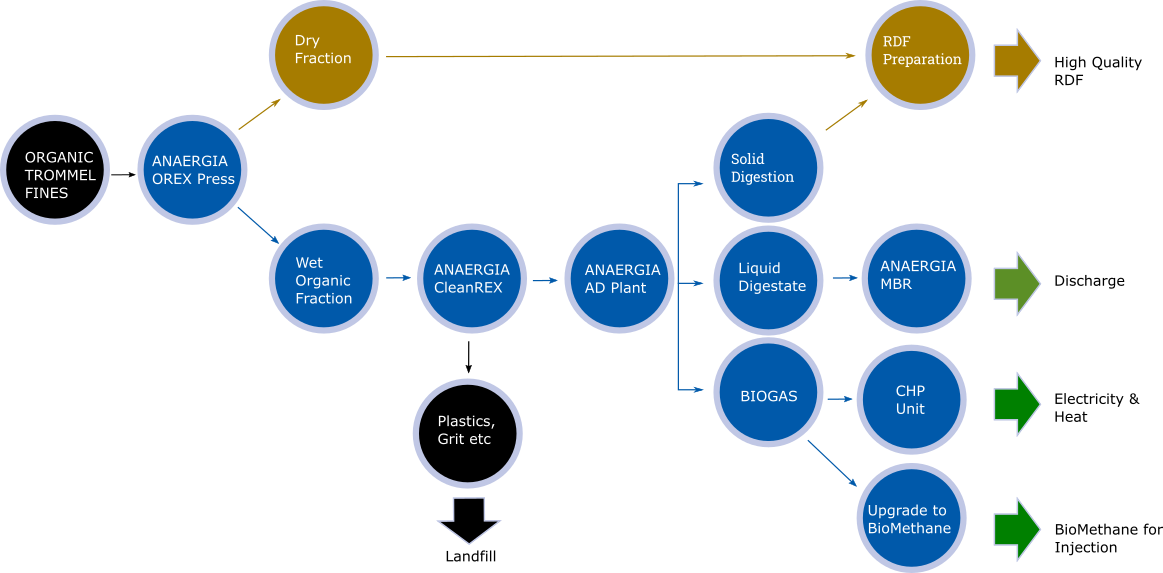

How The OREX Press Processes Trommel Fines From An MRF

Key Anaergia Technologies deployed – OREX Extrusion Press, CleanREX Dynamic Cyclone and FIBREPlate Hybrid Hollow Fibre/Flat Membrane MBR.

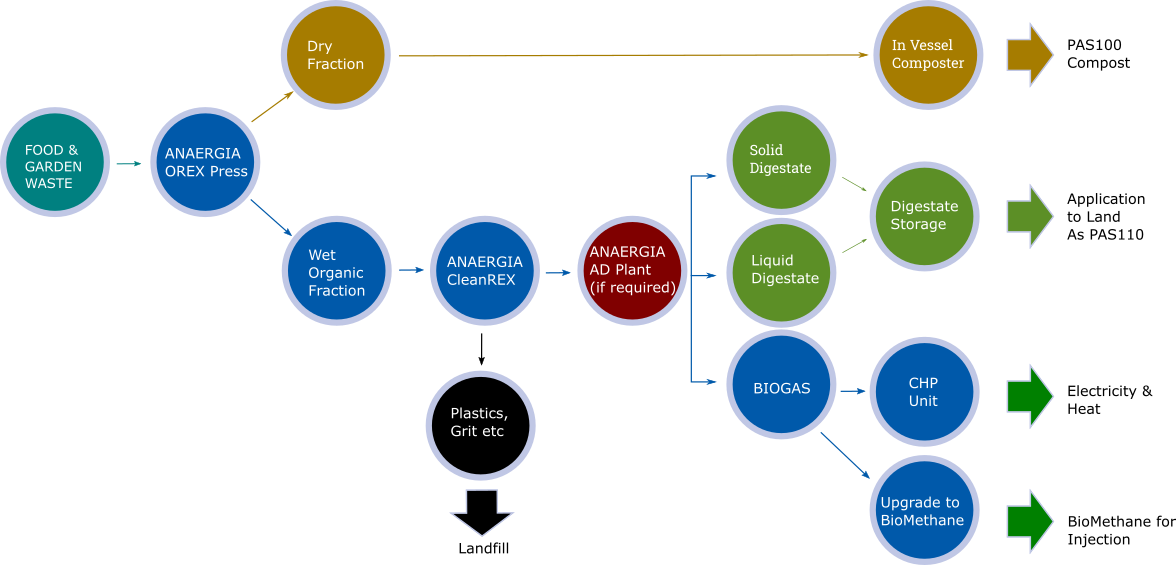

How OREX Helps Assists Local Authorities with Food Waste Management

The OREX enables the diversion of difficult -to-manage organic wastes wastes from landfill. LA can collect food & green wastes together saving time, cost and infrastructure – or collect it separately. The OREX operates very effectively in both situations . Green Waste pressed by the OREX is now ready for processing in a standard AD plant and the AD digestate produced is PAS110 certified.

Anaerobic Digestor

Pre-Treated Food & Garden Waste